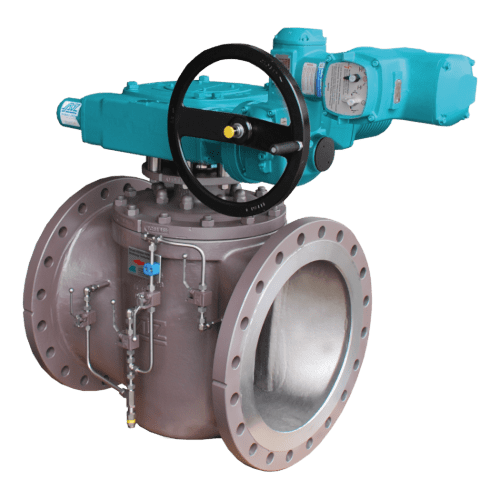

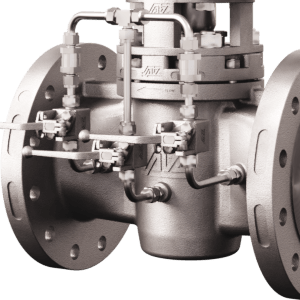

Plug Valve Double Block & Bleed Inspection

- “double block & bleed” with only one valve

- reliable and tight

DN 25 – 600 / PN 10-40

NPS 1 – 24 / Class 150-300

Reliably Working for our Customers

Industries

Storage • Refinery • Transport • Energy

Media

Oil • Gas • Jet fuel • Diesel • Sulfuric acid • Chlorine oxide ClO2

Functional Principle

- AZ plug valves with two self-sealing elements Block 1 and Block 2

- Closing of the plug valve seals off Block 1 and Block 2

- Open the bleed valve for tightness testing

- Inspection and revision services using inspection valves I+II

Design Features

Design Characteristics

- PTFE-sleeved plug for large sealing surface – reliable and tight

- “double block & bleed” possible with only one valve

- suitable for critical service

- long durability – adjustable plug

- outlet positions customized

- cost saving compared to 2 valve system

- alternative to traditional “lift and turn” plug valves

- Firesafe acc. to API 607 / ISO 10497 (only externally)

- TA – Luft approval

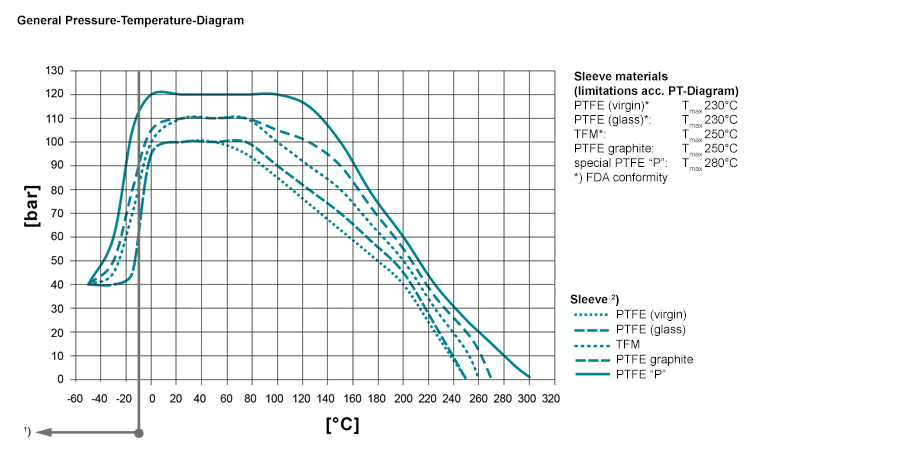

PT-Diagram

Operating temperatures < -30°C and > 220 °C have to be checked and approved by AZ according to the operating conditions.

Besides the P/T value of the sleeve the limitations of the valve bodies also have to be considered. Please refer to the EN 12516-1 resp. ASME B16.34 in order to choose a proper pressure rating (PN/class). The shown values refer to austenitic stainless steel 1.4408 (A351 Gr. CF8M).

1) For operating temperatures below -10°C low temperature / austenitic steels are required.

2) Sleeve: There are different sleeve materials / compounds available.

Materials

Standard body materials

• Carbon Steel 1.0619, ASTM A216 WCB

• Stainless Steel 1.4408, ASTM A351 CF8M

• Stainless Steel 1.4308, ASTM A351 CF8

• Unalloyed stainless steel casting (low Temp.) 1.1138, LCC/LCB/A352

Standard plug materials

• Stainless Steel 1.4408, ASTM A351 CF8M

• Stainless Steel 1.4308, ASTM A351 CF8

Special materials

• Alloy

• Monel

• Nickel

• Zirconium

• Titan

• Tantal

• other materials on request

Sealing Systems

| Standard sealing for all major applications; Tmax 230°C Type STDread more [...] | Firesafe safety sealing (API 607) for fluctuating temperatures with 3x graphite packing (adjustable) for additional stem sealing; Tmax 280°C Type FSNread more [...] |

| Firesafe sealing (API 607) with graphite packing for additional stem sealing; Tmax 230°C Type FSread more [...] | Firesafe safety sealing (API 607) for fluctuating temperatures with 3x graphite packing (live loaded disc springs) for additional stem sealing; Tmax 280°C Type FSN-SLread more [...] |

| Chemical sealing to prevent fugitive emission of aggressive and toxic media with PTFE packing for additional stem sealing; Tmax 230°C Type CAread more [...] | Chemical safety sealing for fluctuating temperatures with 3x PTFE packing (adjustment) for additional stem sealing; Tmax 230°C Type CASNread more [...] |

| Chemical safety sealing for fluctuation temperatures with 3x PTFE packing (live loaded disc springs) for additional stem sealing; Tmax 230°C Type CASN-SLread more [...] |

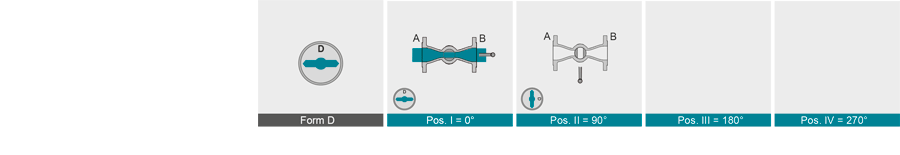

Port Forms

Dimensions

The valve type DBI is available in all common sizes acc. to DIN / ASME

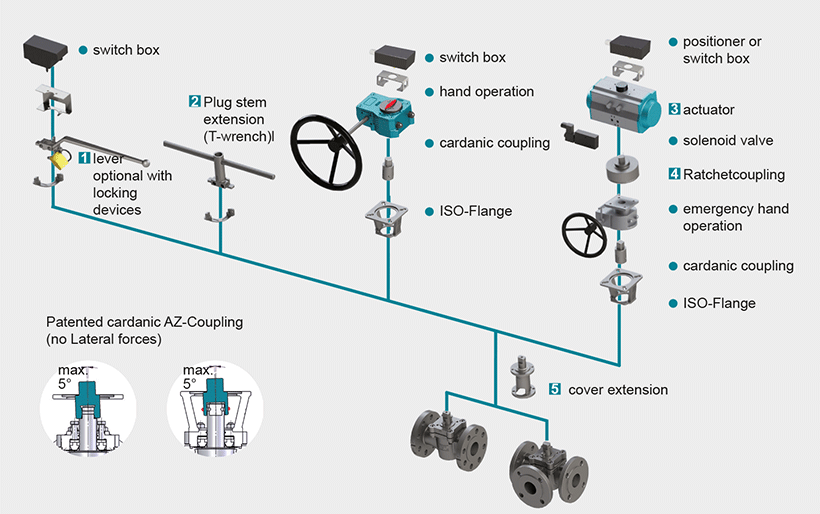

Actuation

1 Locking Devices

Pilot valve combinations, pad lock eyelets, linear key conception, indexing plunger arrestor.

read more […]

2 Plug stem extension

Solid construction in stainless steel with T-wrench, Standard extension 100 mm or 150 mm, non standard lengths are available on request

read more […]

3 Actuators

Actuators for mounting-flange acc. to DIN ISO 5211

read more […]

NEW: Pneumatic actuator AIR GEAR for plug valves with high torque =150.000 Nm

read more […]

4 Ratched coupling

To usw on multiport valves with standard 90° actuator for bigger switchpositions than 90°

read more […]

5 Cover extension

Solid construction in stainless steel, Standard extension 100 mm or 150 mm high, non standard lengths are available on request . Hexagonal bolts on adjustment ring freely accessible. Note: Don’t use with sealing FSN/FSN-SL and CASN/CASN-SL

read more […]

Product Range

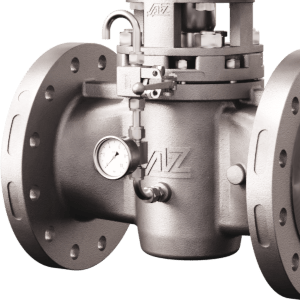

DBI-B

- bleed valve to check tightness when main valve is closed

- bleed outlet standard with “goose neck” pipe

Accessories:

- bleed outlet standard with “goose neck” pipe

- pressure transmitter

- valve automation

- locking device

DBI-B&I

- bleed valve to check tightness when main valve is closed

- inspection valve for inspection and revision services

Accessories:

- manometer/pressure gauge

- pressure transmitter

- valve automation

- locking device

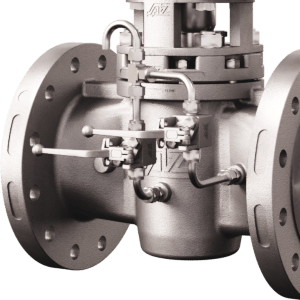

DBI-B&2I

- bleed valve to check tightness when main valve is closed

- inspection valve I and II (upstream / downstream) for inspection and revision services

Accessories:

- manometer/pressure gauge

- pressure transmitter

- valve automation

- locking device

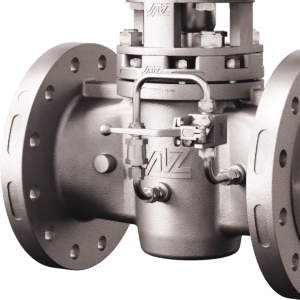

DBI-TR1

- thermal relief system to prevent pressure build-up due to thermal expansion in the plug

- isolation valve in case of service

Accessories:

- bleed valve

- manometer/pressure gauge

- pressure transmitter

- valve automation

- locking device

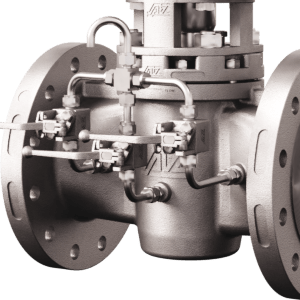

DBI-TR2

- thermal relief system to prevent pressure build-up due to thermal expansion in the plug and downstream pipeline

- isloation valves in case of service

Accessories:

- bleed valves

- inspection valves

- manometer/pressure gauge

- pressure transmitter

- valve automation

- locking device